Sauces

Desserts

Cheesecake

Precooked

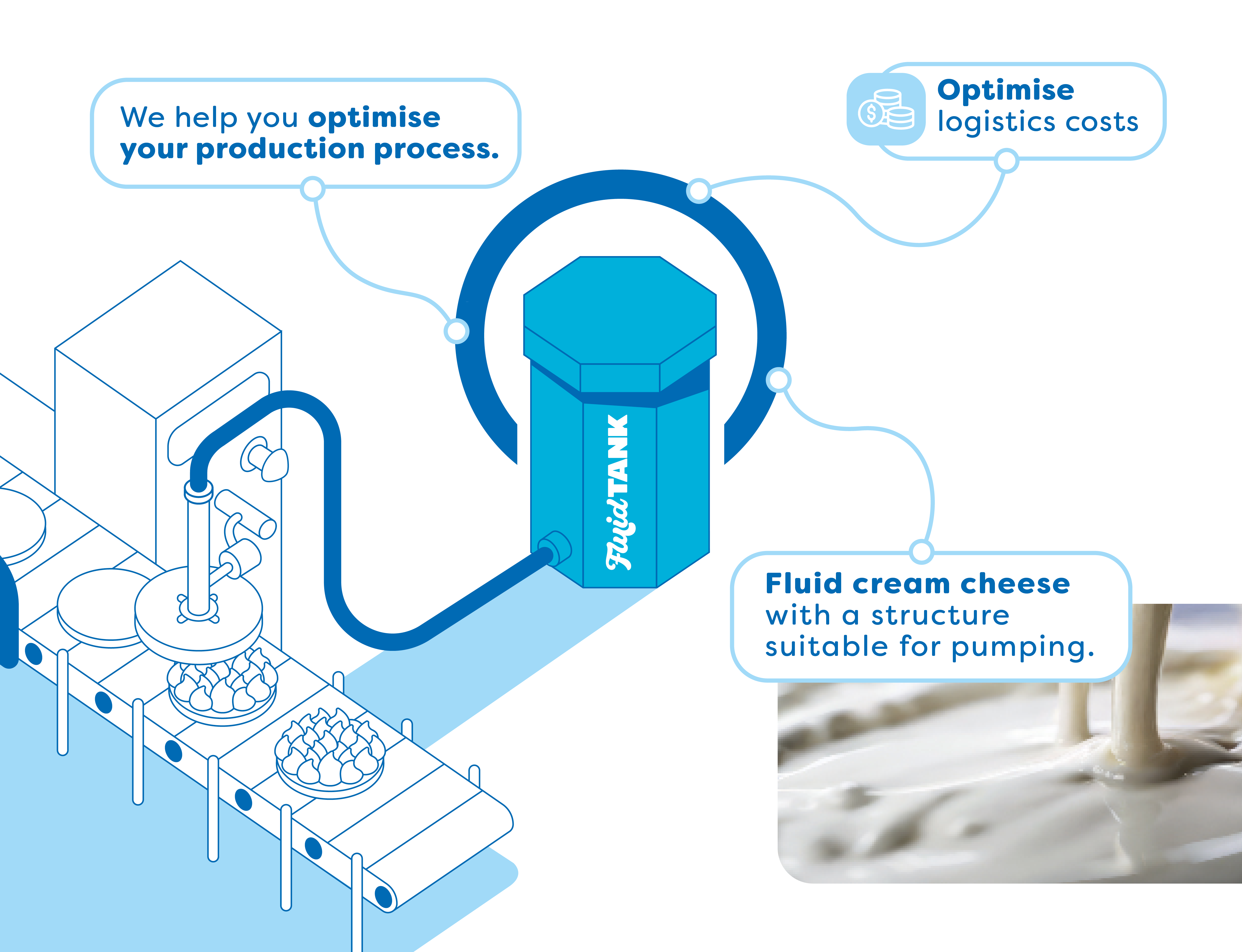

Meet Quescrem FluidTank, an innovative cream cheese that facilitates daily factory operations.

A product with a format of up to 1,000 liters that helps food industries with high consumption and automated processes to save costs, optimize production times and optimize production times and reduce waste.

2. Zero contact with the product

FluidTank ensures a controlled and more hygienic working environment throughout the production process.

Its discharge spout connects the fluid cream cheese directly to the line. No contact with the environment, reduces the risk of microbiological contamination microbiological contamination.

4. Promotes commitment to sustainability

FluidTank facilitates waste management by reducing the use of plastic and cardboard. It has 92% less packaging compared to small formats.

Its sustainable approach reduces the carbon footprint associated with transportation and logistics costs. In addition, it is committed to a responsible and environmentally friendly environmentally friendly production.

Complete the form and learn how to save costs and optimize your resources.

| Inspire your creations with Quescrem!

Fill in the form and receive by e-mail the recipe booklet for professionals with Quescrem products. |

|

| Inspire your creations with Quescrem!

Fill in the form and receive by e-mail the recipe booklet for professionals with Quescrem products. |

|

| Inspire your creations with Quescrem!

Fill in the form and receive by e-mail the recipe booklet for professionals with Quescrem products. |

|

| Inspire your creations with Quescrem!

Fill in the form and receive by e-mail the recipe booklet for professionals with Quescrem products. |

|

| Inspire your creations with Quescrem!

Fill in the form and receive by e-mail the recipe booklet for professionals with Quescrem products. |

|

| Discover Quescrem !

Subscribe and receive news, special communications and original content for professionals in your inbox. |

|